Product Description:

This product serves as a top-quality replacement diaphragm, specially engineered for a wide range of industrial air-operated diaphragm pumps. Crafted with precision, our diaphragms utilize premium raw materials that deliver outstanding flexibility and exceptional wear resistance, ensuring a prolonged service life.

Designed to maintain the continuous and efficient functioning of your diaphragm pump, these diaphragms help minimize equipment maintenance costs and reduce downtime significantly. They are an ideal solution for sustaining optimal pump performance in various industrial applications.

We offer multiple material options tailored to accommodate diverse working environments, fluid properties, and temperature demands. Our selection includes professional-grade materials such as Nitrile Rubber (NBR), Fluorocarbon Rubber (FKM/Viton), PTFE, and Santoprene. These materials guarantee dependable and consistent performance, even under the most challenging operating conditions.

Features:

We offer a variety of material options to meet diverse professional needs. Our products are crafted from high-quality materials such as Nitrile Rubber, Fluorocarbon Rubber, PTFE, Santoprene, and more. These options ensure compatibility with different chemical environments and working conditions.

Our materials provide excellent chemical resistance, specifically formulated to withstand corrosion caused by a broad spectrum of chemicals. This includes acids, alkalis, solvents, and oils, making them highly durable in challenging chemical media.

Designed with superior mechanical properties, the materials exhibit high strength and elasticity. This combination guarantees shape stability and dependable performance, even under frequent reciprocating movement.

With a wide temperature tolerance, our material options can accommodate various operating environments. Whether exposed to low or high temperatures, the products maintain their integrity and functionality.

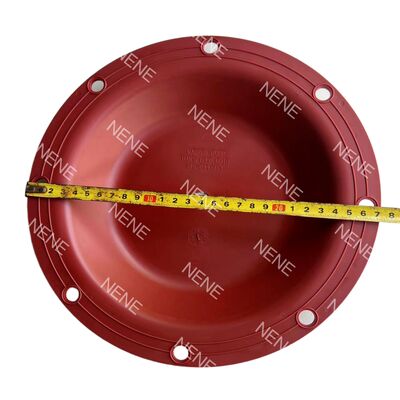

Manufactured through a precision process using carefully crafted molds, each component achieves accurate dimensional standards. This ensures a perfect fit with multiple brands and models of diaphragm pumps, promoting seamless integration.

The optimized design effectively minimizes stress concentrations, significantly extending the service life of the diaphragms. As a result, replacements are less frequent, offering better cost efficiency.

Installation and replacement are straightforward thanks to the user-friendly design. This allows for quick and easy servicing, significantly reducing equipment downtime and enhancing operational efficiency.

Technical Parameters:

| Pump Compatibility |

Wilden, Yamada, Graco, Etc. |

| Certification |

FDA, RoHS Available |

| Material |

NBR / FKM / PTFE / Santoprene |

| Standard Packaging |

1pcs/box |

| Chemical Resistance |

Oil, Acid, Solvent Resistant |

| Operating Temperature |

-20°C To +150°C |

Applications:

Chemical Industry

The chemical industry involves the handling and transfer of a wide range of chemical reagents. This includes the movement of corrosive substances such as acids, alkalis, and various solvents that require careful management due to their reactive nature.

Electroplating & Surface Treatment

In electroplating and surface treatment processes, the circulation and transfer of plating solutions are essential. These typically involve acids and alkalis that must be carefully controlled to ensure effective surface treatment and plating quality.

Paints & Inks Manufacturing

The manufacture of paints and inks requires the transfer of components such as pigments, resins, solvents, and the finished paint products. Each of these materials demands precise handling to maintain product consistency and safety.

Ceramics & Building Materials Industry

Within the ceramics and building materials sector, the transfer of glazes, slurries, and various ceramic raw materials is common. Efficient handling of these substances is vital for the production of high-quality ceramic goods.

Water Treatment Industry

The water treatment industry involves processes such as wastewater treatment, chemical dosing, and sludge transfer. The controlled movement of these materials supports effective purification and environmental management.

Food & Beverage Processing

In food and beverage processing, the transfer of food-grade materials must comply with strict sanitary and safety standards. The use of specialized materials ensures that ingredients are handled in a way that maintains product hygiene and quality.

Pharmaceutical Industry

The pharmaceutical industry requires the careful transfer of pharmaceutical ingredients, intermediates, and auxiliary materials. This process is critical to maintaining product purity and meeting regulatory standards.

Mining & Metallurgy

In mining and metallurgy, the transfer of slurries, flotation agents, and various metallurgical solutions is integral to the extraction and processing of ores. Managing these materials efficiently enhances operational productivity and safety.

Paper Industry

The paper industry involves the transfer of pulp, coatings, and chemical additives. Proper handling of these materials is essential to produce quality paper products and maintain process efficiency.

Support and Services:

Our Pulse Valve Diaphragm product is supported by a dedicated technical support team committed to ensuring optimal performance and longevity of your equipment. We provide comprehensive services including installation guidance, troubleshooting assistance, and maintenance tips to help you maximize the efficiency of your pulse valve systems.

Technical support is available to assist with diaphragm selection, compatibility verification, and replacement procedures. Our experts can help diagnose issues related to wear, leakage, or performance degradation, and recommend appropriate corrective actions.

We also offer customized service solutions tailored to your operational needs, including on-site inspections and preventive maintenance programs designed to minimize downtime and extend the service life of your pulse valve diaphragms.

All our diaphragm products undergo rigorous quality control and comply with industry standards, ensuring reliable and consistent performance. For detailed product specifications, installation manuals, and maintenance guides, please refer to the technical documentation provided with your purchase.

Packing and Shipping:

Each Pulse Valve Diaphragm is carefully packaged to ensure maximum protection during transit. The diaphragm is first placed in a protective plastic sleeve to prevent any dust or moisture damage. It is then securely positioned within a custom-fitted box with cushioning materials to absorb shocks and impacts.

For shipping, we use sturdy outer cartons that are clearly labeled with product information and handling instructions. Depending on the order size, multiple units are packed together in larger cartons to optimize space and reduce shipping costs.

We offer various shipping options to meet delivery requirements, including standard, expedited, and freight services. All shipments are tracked, and customers receive confirmation and tracking details once the order is dispatched.

Our packaging and shipping processes comply with international standards to ensure the Pulse Valve Diaphragm arrives in perfect condition and ready for immediate use.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!